Dual Filter SW-46

November 12, 2024

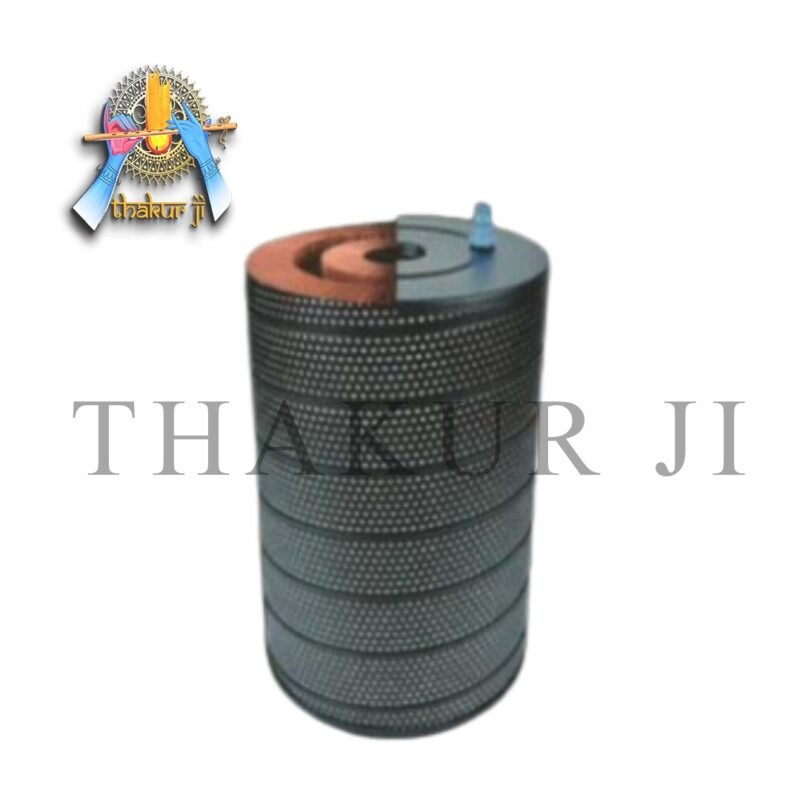

Super Filter Super 250AK

November 12, 2024Super Filter Super 250A

| Name | Details |

|---|---|

| Maker | Mitsubishi/Brother/Hitachi |

| Size | 300×29×250 |

| Pressure | IN |

| Coupler | Without |

| Specification | DWCF, G, H, SX Series, HS-300, 350, 3100, 3600, H-Cut 304, 406, 460 |

Application:

The EDM Super Filter is used in high-precision and high-performance EDM machines where the purity of the dielectric fluid directly affects the quality of the machining process. Key applications include:

Wire EDM Machines: In wire EDM, where fine particles are generated during the wire cutting process, the EDM Super Filter ensures that the fluid remains clear of contaminants, contributing to more accurate cuts and better surface finishes.

Die-Sinking EDM Machines: For die-sinking EDM, which involves intricate designs and complex workpieces, the super filter helps maintain fluid cleanliness, which is essential for achieving fine details and smooth surfaces.

Precision Hole Drilling EDM: In precision hole drilling applications, where extremely tight tolerances are required, the EDM Super Filter ensures that even the smallest particles are removed from the dielectric fluid, maintaining the highest accuracy.

High-Speed Machining: In high-speed EDM processes, where heat and debris are produced rapidly, the super filter works efficiently to keep the dielectric fluid free from contaminants, enhancing performance and reducing the risk of tool wear or clogging.

Medical Device Manufacturing: In industries such as medical device manufacturing, where cleanliness and precision are critical, the EDM Super Filter ensures the dielectric fluid remains free of impurities, supporting high-quality machining outcomes.

Advantages:

Ultra-High Filtration Efficiency: The multi-layered structure and advanced filtration media allow the super filter to remove the finest particles, including sub-micron debris, ensuring the highest fluid purity.

Improved Surface Quality and Accuracy: With cleaner dielectric fluid, EDM processes achieve better electrical discharge stability, leading to improved surface finishes and more precise machining, which is essential for industries requiring high-quality parts.

Extended Machine Life: By preventing fine particles from circulating through the EDM system, the super filter reduces wear on the machine components, extending the lifespan of the equipment and reducing maintenance costs.

Consistent Performance: The super filter ensures that the dielectric fluid remains clean over extended periods, maintaining consistent EDM performance without fluctuations in machining quality.

Reduced Downtime: The high debris-holding capacity of the super filter means it requires fewer replacements, minimizing downtime for filter changes and keeping the EDM machine running smoothly for longer.

Cost Efficiency in the Long Run: While the initial investment may be higher compared to standard filters, the EDM Super Filter’s durability, long service life, and high performance lead to long-term savings on maintenance and operational costs.

Better for Complex and High-Precision Work: The super filter is ideal for industries that require complex, high-precision EDM work, such as aerospace, automotive, medical, and electronics, where the purity of the fluid plays a major role in achieving the desired outcomes.