Brass Electrode Tube Multi Hole (Multi Channel)

November 16, 2024

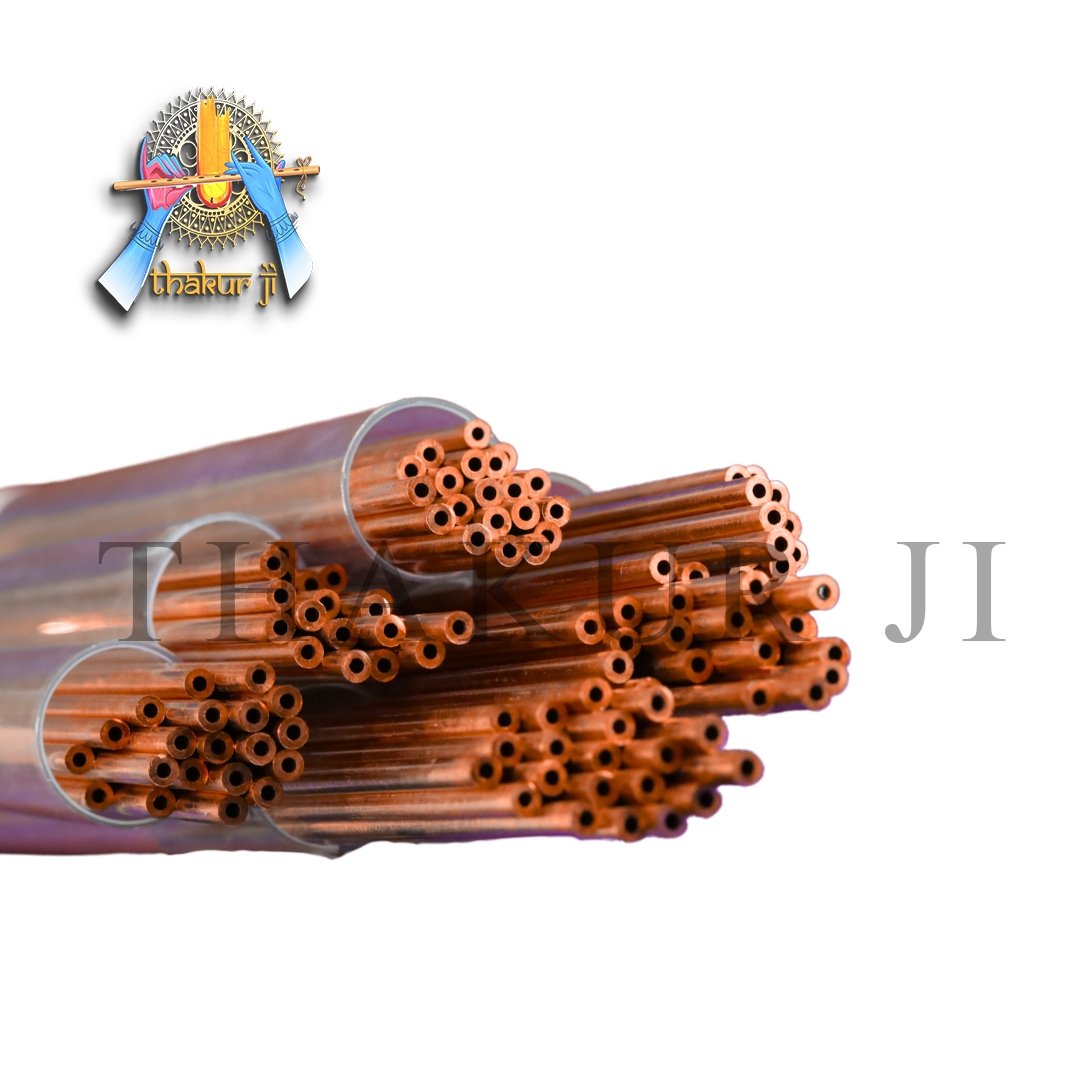

Copper Electrode Tube Multi Hole (Multi Channel)

November 16, 2024Copper Electrode Tube Single Hole (Single Channel)

| Description | 0.11*200mm Copper electrode tube single hole, single channel |

| Size | 0.11*200mm |

| Application | EDM drilling machine |

Application:

EDM Drilling: Essential for high-precision drilling in electrical discharge machining (EDM) processes.

Cutting Hard Materials: Used for materials with high hardness, such as tungsten steel, brass, and copper alloys.

Precision Manufacturing: Ideal for industries requiring high-quality, high-precision drilling in a wide range of materials.

Advantages:

High Copper Content: The use of T2 red copper ensures superior conductivity and overall performance.

Fast Drilling Speed: The copper pipe facilitates rapid discharge of water and materials, reducing drilling time.

Wear Resistance: The material is highly resistant to wear, ensuring longer tool life and efficiency.

High Perpendicularity: Achieves precise and perpendicular drilling, essential for quality EDM work.

Excellent Surface Finish: Both internal and external surfaces are finely finished, minimizing defects in the drilled workpiece.

Corrosion Resistance: Strong resistance to corrosion, extending the life of the electrode tube and enhancing reliability in harsh conditions.

Wider Material Compatibility: Can be used with a wide range of materials, offering flexibility for different EDM applications.

| Parameter | Description |

|---|---|

| Specification | 0.3 – 3.0 mm |

| Size | 400 mm – 500 mm |

| Material | T2 Red Copper (Higher copper content) |

| Raw Material | Processed from high-quality T2 red copper, ensuring excellent quality and performance |

| Processing Technology | Strict, advanced processing technology ensures high standards of production and quality |

| Performance Features | – Stable performance – Fast drilling speed – Wear resistance – High perpendicularity |

| Surface Finish | High internal and external surface finish |

| Corrosion Resistance | Strong corrosion resistance |

| Application Materials | Copper, brass, tungsten steel, Kg5, W88%, CO12%, tin, and high-hardness materials |