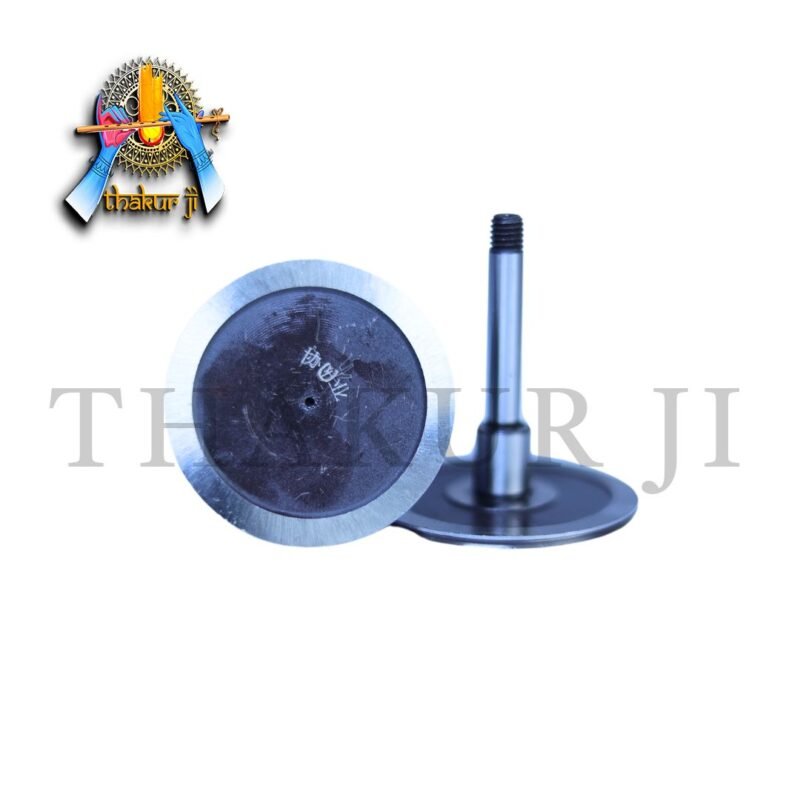

Tungsten Disk

November 27, 2024

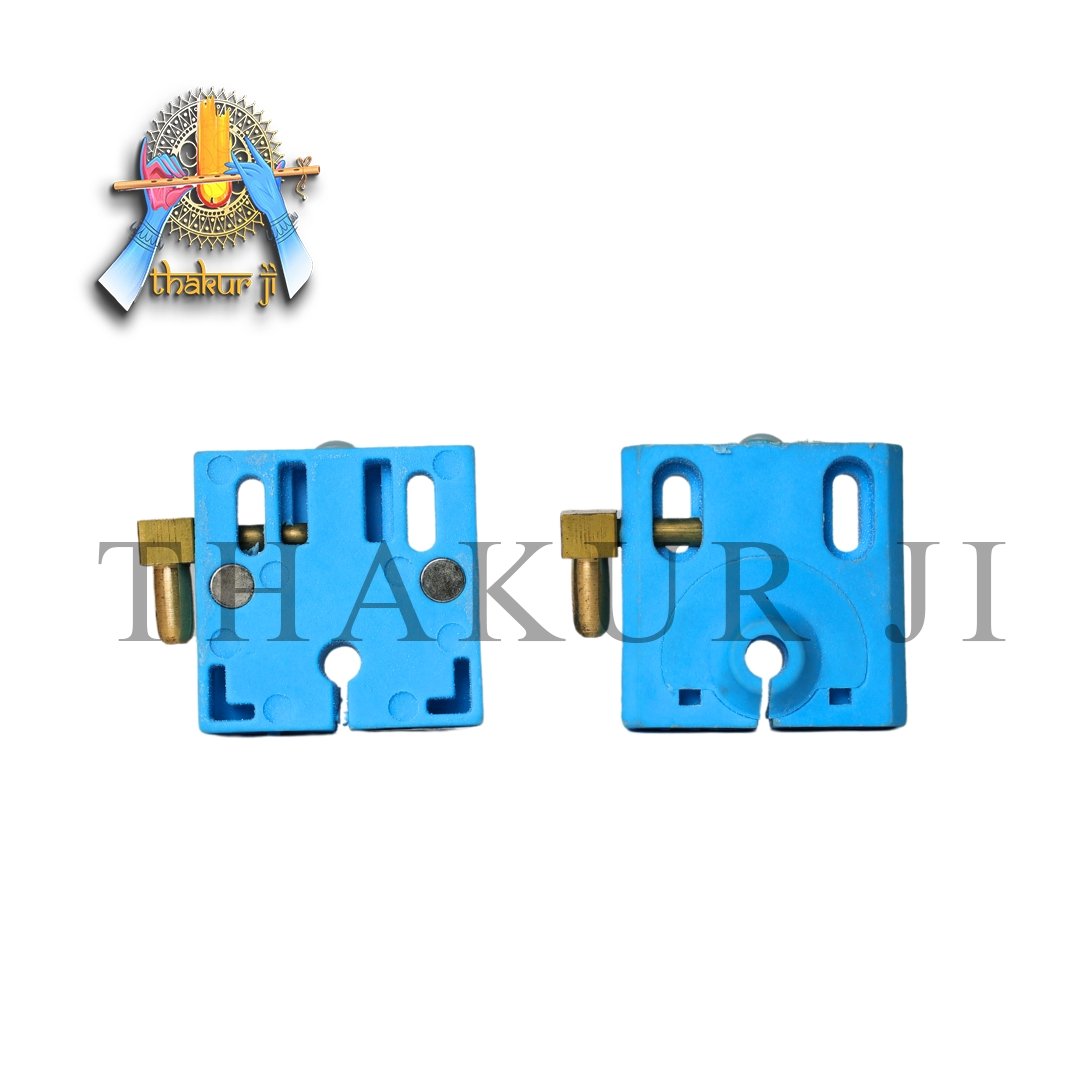

Molybdenum Tightener 3 Roller

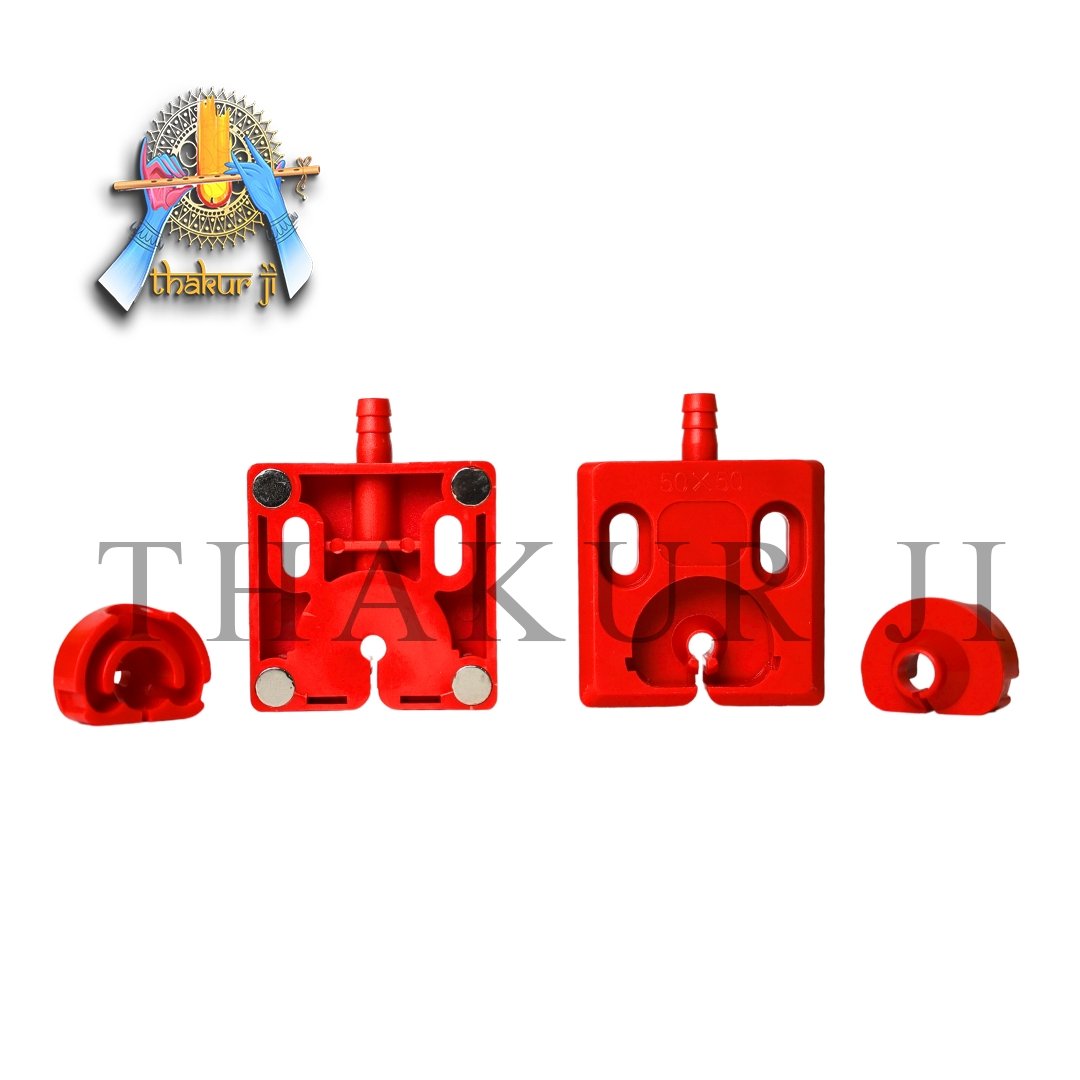

November 27, 2024Edm machine water nozzle

Application:

Mold & Die Making: Ensures precision cutting, essential for manufacturing molds used in casting and injection molding.

Aerospace & Automotive Industries: Facilitates high-precision machining of critical components like turbine blades and engine parts.

Tool and Die Production: Efficiently cuts high-hardness materials, vital for tool and die manufacturing.

Medical Device Manufacturing: Ensures precise cutting of small, intricate components, critical in medical instruments and implants.

Electronics Industry: Supports the creation of detailed electronic components requiring fine tolerances.

Prototyping: Helps produce prototypes with high accuracy for testing and development.

Advantages:

Efficient Cooling: Prevents overheating by directing the dielectric fluid precisely to the cutting zone.

Debris Removal: Flushes away melted material and particles, reducing the risk of clogging and improving cutting efficiency.

Enhanced Precision: Maintains a stable cutting gap between the wire and the workpiece, ensuring high accuracy.

Improved Wire Stability: Stabilizes the wire electrode, preventing deflection or breakage during the process.

Minimized Spark Interference: Regulates the dielectric fluid flow, reducing unwanted sparks and enhancing machining accuracy.

Durability: Long-life nozzles reduce maintenance costs and machine downtime.

Flexibility: Adjustable nozzles provide versatility for various materials and cutting requirements.

Cost-Effectiveness: Proper use enhances machine life and reduces overall operational costs.

| Parameter | Details |

|---|---|

| Material | High-strength polymers or metals like brass, stainless steel, or ceramics. |

| Shape and Size | Tapered or cylindrical design; customizable to fit specific EDM machines. |

| Flow Rate | Adjustable, typically calibrated for optimal dielectric fluid delivery. |

| Pressure Range | Supports high-pressure fluid delivery, preventing overheating and stabilizing the cutting zone. |

| Nozzle Type | Standard, high-precision, adjustable, or long-life nozzles tailored for various applications. |

| Durability | Long-lasting with wear-resistant coatings or materials. |

| Compatibility | Designed to fit a wide range of EDM wire-cut machines, such as Sodick, Mitsubishi, or Charmilles. |

| Temperature Resistance | Can withstand high temperatures generated during the cutting process. |

| Precision Features | Uniform flow channels to maintain consistent dielectric fluid application and enhance cutting accuracy. |

| Maintenance | Easily replaceable; designed for minimal wear to reduce downtime. |