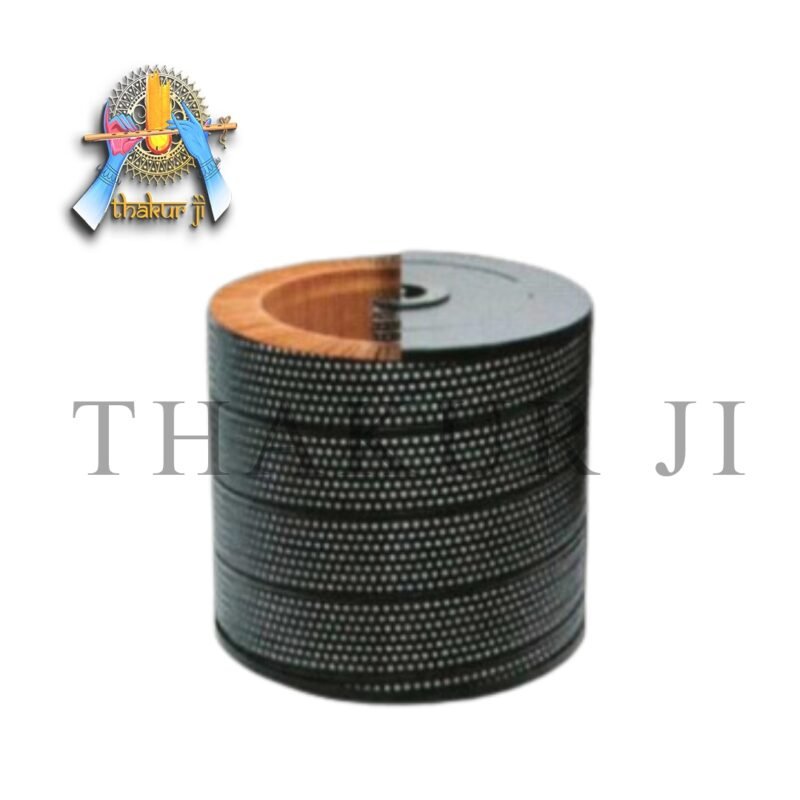

Oil Filter SO-18M

November 12, 2024

Oil Filter SO-34

November 12, 2024Oil Filter SO-24

| Name | Details |

|---|---|

| Maker | Mitsubishi/Sodick |

| Size | 260×29×340 |

| Pressure | IN |

| Specification | M Series, J, V, DP, A Series, AH, K Series |

Application:

The EDM Oil Filter is used primarily in oil-based EDM machines, where dielectric fluid is used to facilitate the discharge process and cool the cutting tool. Key applications include:

Oil-Based EDM Machines: Used specifically in EDM machines that utilize oil as the dielectric fluid. These filters help maintain the purity of the oil, which is essential for smooth and precise electrical discharges during machining.

High-Precision Die-Sinking EDM: In die-sinking EDM operations, where high-precision workpieces are created, the oil filter ensures that the dielectric oil is free of contaminants, which can affect the accuracy of the electrical discharge and the surface finish.

Wire EDM Machines with Oil-Based Fluids: When wire EDM machines use oil as a dielectric fluid, the EDM Oil Filter is crucial to ensure the fluid remains clean, reducing the risk of contamination that could disrupt the wire cutting process.

Oil Hole Drilling EDM: In EDM hole drilling processes that use oil-based dielectric fluids, oil filters help prevent the buildup of fine particles and contaminants, allowing for consistent and accurate hole drilling operations.

Advantages:

Superior Filtration Efficiency: The multi-layer filtration system ensures that both large and fine particles are removed from the oil, maintaining fluid purity and ensuring the EDM process remains smooth and precise.

Enhanced Surface Quality and Precision: Clean oil helps ensure that the electrical discharges remain stable, leading to better surface finishes and more precise machining, particularly for high-precision tasks like die-sinking and wire cutting.

Longer Oil Life: By removing contaminants from the oil, the EDM Oil Filter extends the lifespan of the dielectric oil, reducing the need for frequent oil changes and saving on operational costs.

Reduced Wear and Tear on EDM Machines: Contaminants in the dielectric oil can cause excessive wear on EDM machine parts. By keeping the oil clean, the filter helps protect critical machine components, extending the machine’s overall lifespan.

Improved EDM Machine Performance: Clean oil leads to stable electrical discharges, improving the overall performance of the EDM machine, reducing defects, and ensuring consistency in machining results.

Cost Savings: While the initial cost of the EDM Oil Filter may be higher than simpler filtration systems, its efficiency in maintaining fluid cleanliness results in lower maintenance costs and fewer oil replacements, providing long-term savings.

Low Maintenance and Easy to Replace: EDM Oil Filters are designed for easy removal and replacement, ensuring minimal downtime during maintenance. Their long lifespan and high debris-holding capacity also reduce the frequency of replacements.