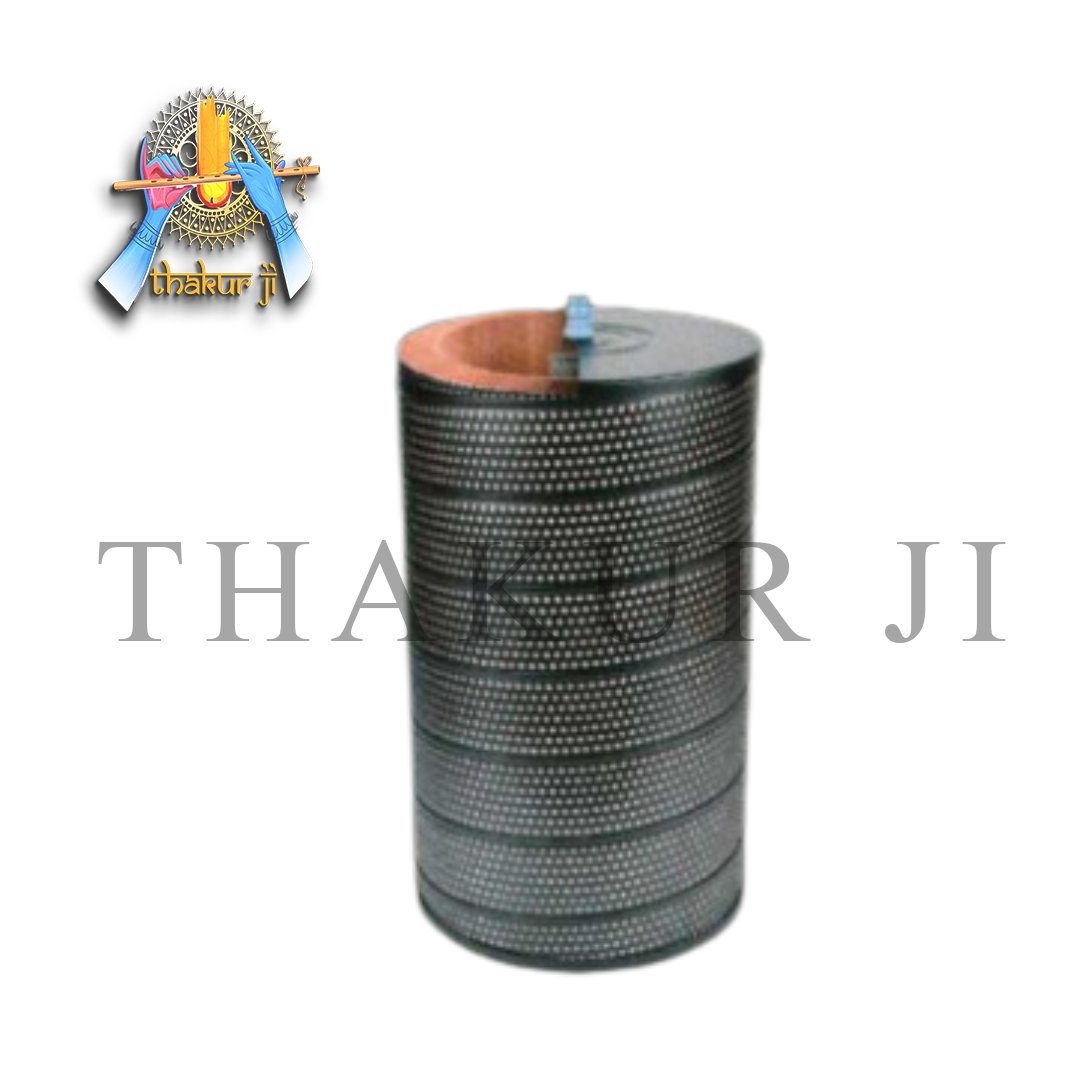

OMF Filter OMF 500A

November 12, 2024

OMF Filter OMF 340F (SW-35)

November 12, 2024OMF Filter OMF 500AK

| Name | Details |

|---|---|

| Maker | Mitsubishi/Makino/Hitachi / Seibu |

| Size | 300×500 |

| Pressure | IN |

| Coupler | Center Nipple |

| Specification | DWC-110PA/EE, EQ, EQH/Q,

H-Cut-Q Series/EW-A5, A5S, C3 |

Application:

The OMF Filter is used in various EDM applications to provide superior filtration, maintaining the purity of dielectric fluids crucial for precision machining. Key applications include:

Wire EDM Machines: Essential for wire EDM processes where high filtration efficiency is required to handle fine particles produced during cutting.

Precision Die-Sinking EDM: Used in operations requiring extremely accurate cuts, the OMF filter ensures the dielectric fluid remains free of even the smallest contaminants.

High-Performance Hole Drilling: In high-speed hole drilling EDM, OMF filters are used to keep the fluid clean, preventing any micro-particles from impacting the drilling accuracy.

Complex Component Manufacturing: Industries requiring complex shapes and designs, like aerospace and automotive, rely on OMF filters to maintain the integrity of the EDM process.

Advantages:

Superior Filtration Efficiency: The multi-layered structure and high-density pleating enable the OMF filter to remove finer particles than standard EDM filters, leading to better machining results.

Enhanced Surface Finish: By maintaining cleaner dielectric fluids, the OMF filter contributes to improved surface quality of the machined parts, reducing the need for additional finishing processes.

Longer Filter Life: The advanced design allows OMF filters to hold more debris without clogging, extending the time between replacements and reducing maintenance downtime.

Stable EDM Performance: Cleaner fluids ensure consistent electrical discharge, resulting in better machining stability and fewer defects during the EDM process.

Cost Savings: Although OMF filters may have a higher upfront cost, their longevity, reduced maintenance needs, and superior filtration efficiency can lead to overall cost savings in EDM operations.