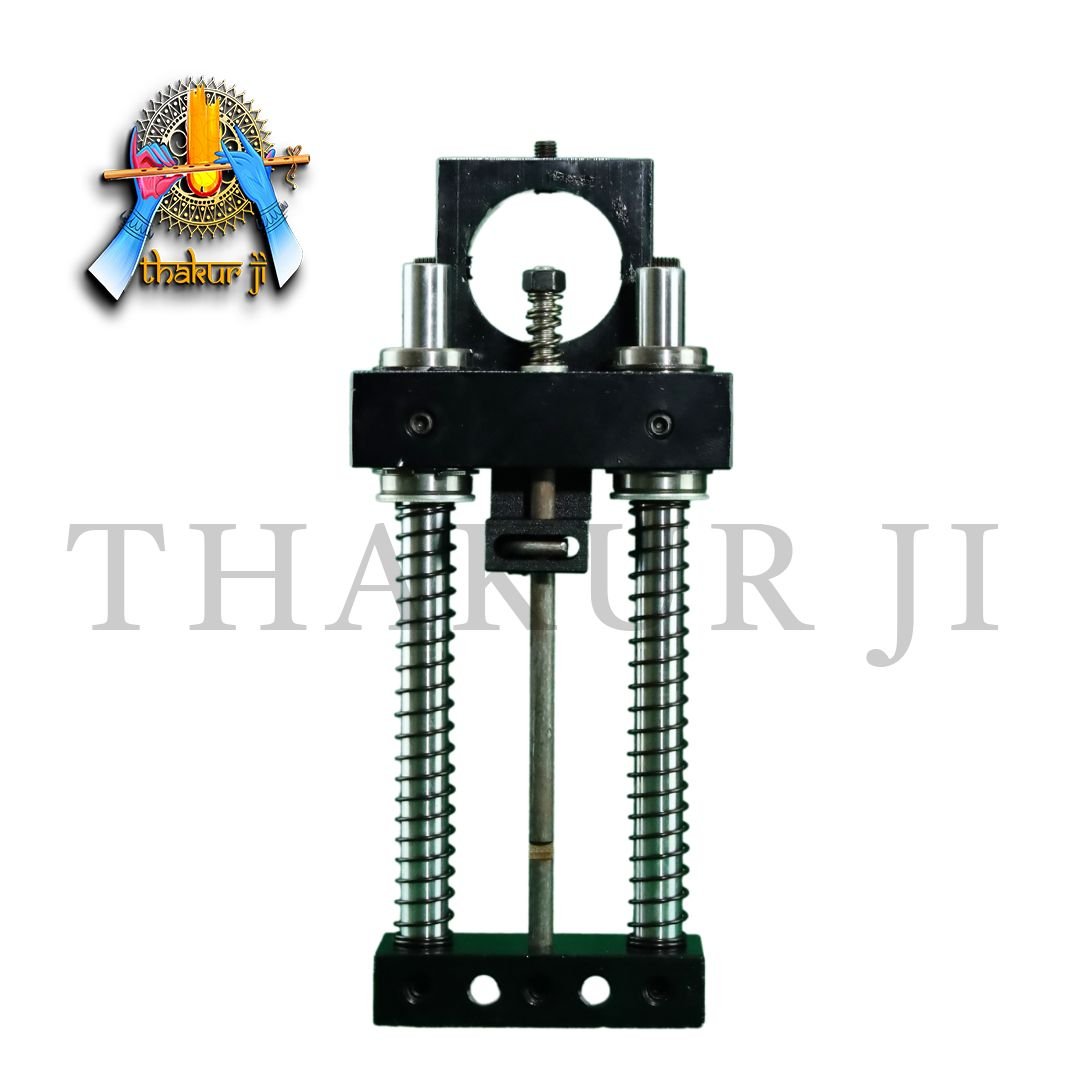

Wire Cut Copper Guide Wheel Assembly V-42-60-C

November 27, 2024

Ceramic Tube Guide 0.3mm

November 27, 2024Molybdenum Wire Tightener (65x22x32)mm

Application:

EDM Wire-Cutting Machines: Maintains proper tension and alignment of the wire during cutting operations.

Ensures smooth operation and precise cuts.

Metalworking Industries: Ideal for high-precision machining tasks where stability and alignment are critical.

Aerospace and Defense: Utilized in components requiring high heat resistance and strength.

Electronics Industry: Used in applications needing precise metal shaping or cutting.

Automotive Manufacturing: Applied in machining tools and parts for precision engineering.

Advantages:

High Precision: Ensures accurate tension and alignment, leading to improved cutting quality.

Durability: Made from molybdenum alloy, offering long-lasting performance under high stress.

Heat Resistance: Operates efficiently at high temperatures, ideal for demanding EDM processes.

Corrosion Resistance: Resistant to rust and wear, ensuring longevity even in harsh environments.

Lightweight Yet Strong: Easy to install and handle without compromising strength.

Customizability: Available in various sizes and configurations to meet specific needs.

Energy Efficiency: Reduces friction and energy consumption during operations.

Cost-Effective: Minimizes maintenance and replacement costs due to high durability.

| Parameter | Specification |

|---|---|

| Material | Molybdenum Alloy |

| Dimensions | Customizable (Standard: Diameter 30-50mm, Width 20-40mm) |

| Hardness | High Hardness (HRC 40-50) |

| Heat Resistance | Up to 1200°C |

| Surface Finish | Precision Polished |

| Load Capacity | High Load Capacity (up to 500kg) |

| Weight | Lightweight, depending on size configuration |

| Corrosion Resistance | Excellent, suitable for EDM wire cutting environments |

| Compatibility | Compatible with various EDM wire-cutting machines |

| Customization | Available (Shape, Size, and Specifications) |